Journal of Crystal Growth 125

(1992) 215-222

North-Holland

Ó1992 – Elsevier

Science Publishers B.V. All rights

reserved

Calcium oxalate monohydrate crystallization: citrate inhibition of nucleation and growth steps

Peter

A. Antinozzi, Charles M. Brown and Daniel L. Punch

Center for the Study of

Urolithiasis and Pathological Calcification and Department of Biochemistry and

Molecular Biology, University of Florida College of Medicine, Gainesville,

Florida 32610-0247, USA

Received 30 March 1992;

manuscript received in final form 29 June 1992

The inhibitory action of citrate on calcium oxalate monohydrate (COM)

crystallization has been examined in terms of nucleation and crystal growth

kinetic properties. Lag-time data for the appearance of crystals and [‘4C]

oxalate incorporation under crystal growth conditions allowed us to investigate

the influence of citrate at physiological levels (3.5mM). Moreover, through the

use of the EQUIL software, we formulated our solutions based on calculations of

solute composition such that free calcium concentrations were the same in the

absence and presence of this tricarboxylic acid. The presence of citrate had

little effect on the apparent interfacial free energy as determined by

nucleation kinetic studies, but total particle production was greater in the

absence of citrate; this was evident from electron microscopy and was also

indicated by corresponding values of pre-exponential terms of the Gibbs—Thomson

equation. Crystal growth rates were lowered in the presence of citrate to 30%

of the uninhibited value, and distinctive morphological habit modifications

were also observed by scanning electron microscopy. Together, these findings

suggest that citrate may influence COM crystallization at several stages, and

we present a model for face-specific growth inhibition by citrate acting on the

(010) COM crystal face.

1. Introduction

Understanding the factors that influence the course of calcium oxalate

monohydrate (COM) crystallization promises to provide insight about processes

thought important in urolithiasis. In particular, much attention has been

devoted to the analysis of crystallization in terms of discretely defined

physical chemical processes (i.e., nucleation, crystal growth, aggregation, and

breakup) although such processes may be overlapping in a temporal sense.

Nonetheless, such a physicochemical treatment may afford a means of

understanding the action of agents that promote or inhibit COM crystallization.

Brown et al. [1] recently described several approaches for distinguishing

between crystal growth and nucleation effects, and they attempted to

distinguish between the interfacial free energy term and the “nucleation

efficiency” term that are related to the lag-time for crystallization by use of

the

Gibbs—Thomson

equation. We were motivated by the success of that experimental approach to investigate

the action of citrate as an inhibitor of COM crystallization. About half a

century ago, Greenwald [2] first recognized the complexation of calcium ion by

various organic acids, among them citrate, and he discussed the physiological

significance of the sharp increase in the solubility of salts such as calcium

sulfate, calcium carbonate and calcium phosphate as brought about by malic and

fumaric acids. Kissen and Locks [3] established that the urinary citrate levels

of patients suffering from urolithiasis were reduced compared with control

subjects, and many other investigators have labored to characterize the basis

for such a difference and/or its impact on crystallization. The implication

that citric acid is a factor in urolithiasis promoted efforts both to

understand its ability to dissolve kidney stones and its role in their

formation. In 1961, Light and Zinsser [4] examined the rate of formation of

calcium oxalate in the presence of various substances found in urine,

including citrate, and in fact, they studied nucleation rates by observing

lag-times. Subsequent studies of the inhibitory action of citrate focused on

determinations of crystal growth viewed in its broadest sense (i.e., there are

many steps in the formation of a solid phase from an aqueous solution, and a

substance influencing any of these steps may be called an inhibitor). For

example, complexation reduces the driving force for crystal growth, and this

effect must be distinguished from those that influence incorporation of lattice

ions into the crystal. Even some recent crystal growth studies have overlooked

this distinction [5] and

experimental results represent a convolution of metal-ligand complexation and

true growth inhibitory effects.

In this work, we applied nucleation kinetic [1] and crystal growth rate

experiments to analyze the action of citrate on COM nucleation and crystal

growth. We used the EQUIL speciation software [6] to achieve desired relative

supersaturations (RS) with respect to calcium oxalate monohydrate (COM) while

keeping the RS in control solutions and citrate-containing solutions unchanged.

Moreover, to minimize changes in the [Ca2+]free/[OX>]tree

ratio, we maintained constant free ionic calcium, [Ca2+ ]free and free ionic

oxalate, [OX2~]free, concentrations for the

control and experimental solutions of corresponding RS values, achieving a

virtually constant ratio for all solutions. This ratio also controls surface

charging and the zeta potential of the COM surface [7,8], and may therefore

influence crystal growth.

2. Materials and

methods

Solution

preparation. Reagent grade chemicals were used without further

purification, and water of 10 M12 conductivity was produced with a MilliQ high

purity water system. All solutions were filtered through 0.22 ~tm Millipore GS

filters (4.7 cm diameter) and cation concentrations were determined with a

Perkin-Elmer atomic absorption spectrophotometer. Calcium and oxalate concentrations

were adjusted to achieve desired relative

supersaturation

(RS) values, with RS defined as the calcium-oxalate ion activity product

divided by its equilibrium value. At each RS, two reactant solutions were

prepared, one containing potassium oxalate and the other calcium chloride dihydrate.

Typically, the buffered solution consisted of 0.1M sodium chloride, 0.O1M

HEPES, and determined levels of either potassium oxalate or calcium chloride

dihydrate. The solutions were maintained at 370C and pH was adjusted

to 6.5. The

total calcium and oxalate levels in each were chosen using EQUIL to ensure that

uncomplexed Ca2~ was the same for samples with and without citrate.

The second constraint in the EQUIL computations was to maintain the relative

super-saturations of each pair of samples (i.e., with and without citrate).

Calculated concentrations of free ionic and complex species for calcium oxalate

monohydrate solutions in the presence and absence (values in parentheses) of

citrate at a relative supersaturation of 19.7 (pH 6.5): total citrate, 3.5mM (none);

sodium ion, 99.8mM (99.8mM); potassium ion, 1.60mM (1.88mM); calcium ion,

0.73mM (0.72mM); chloride, 106mM (102mM); oxalate, 0.51mM (0.49mM); citrate,

1.17mM (none); HEPES (unprotonated), 1.34mM (1.33 mM); HEPES (protonated),

8.66mM (8.67mM); potassium chloride, 19.8mM (22.7mM); monohydrogen

oxalate ion, 1.51~tM (1.48~tM); monosodium oxalate ion, 1751LM (230j.tM);

mono-potassium oxalate ion, 0.044mM (0.052mM); calcium

oxalate, 121mM (121mM); dicalcium

oxalate ion, 6.27mM (6.18mM); calcium

dioxalate ion, 1.06mM (1.02mM); calcium

hydrogen oxalate ion, 0.021mM (0.021mM);

monohydrogen citrate, 0.28mM (none); dihydnogen citrate, 2.O5btM (none);

monopotassium citrate, 6.65mM (none); calcium citrate

anion, 2.02mM (none); calcium hydnogen cjtrate, 16.6mM (none). Between citrate-containing

and control solutions, uncomplexed Ca2 + levels agreed within 1%, and

uncomplexed Ox2 - within 4%; correspondingly,

surface charge effects on COM due to variation in [Ca2 + ]tree were minimized.

Nucleation. A typical run

began by rapidly mixing 2.5 mL each of the two

reactant solutions by manually pushing the fluids through an in-line helical

mixer into a 1 cm pathlength polystyrene

Fig. 1. Typical

turbidity plot used for lag time measurements. RS 37 with 3.5mM citrate. r =

100 s.

cuvette.

We chose polystyrene because glass, quartz, and acrylic cuvettes produced

appreciable growth on their surfaces. Turbidity was measured for 10 mm using a

Perkin-Elmer 559A UV/VIS spectrometer in absorbance mode at 530 nm. Lag-times,

r, were determined from plots of absorbance versus time (fig. 1). The selected

RS range was based on the behavior of turbidity measurements with respect to

increasing RS. Below RS 20, the turbidity increase did not exceed 0.05 absorbance

units, and lag-times resulting from small deviations above the baseline were

considerably less certain. Above RS 37, lag-times were under 30 s. A typical

experimental run is shown in fig. 1 where the dashed line indicates how the

lag-time was evaluated by extrapolating to a turbidity value of zero; for

example, in the case of citrate-containing systems at RS 19.7, the lag-time was

86 + 17 s. This method gave reproducible

estimates of the apparent nucleation lag-time. Therefore, we examined the

dependence of r on changes in the initial relative supersaturation of calcium

oxalate. Apparent interfacial free energy, s, was evaluated by plotting

ln(1/r) versus (ln RS)2 at six different relative supersaturation

values to produce a linear plot (fig. 2); s was obtained from the slope of the line as defined by the

Gibbs-Thomson equation [9]:

J=A exp[(-16ps3v2)/(3k3T3m2[ln(RS)]2)], (1)

where

J is

the nucleation rate which is proportional to 1/t (s-1), A the

pre-exponential factor, s the apparent interfacial

surface energy (erg cm-2, v the molecular volume (for

COM, 1.10 x 10-22 cm3), k the Boltzmann constant

(1.38 x 10-16 erg K-1), T the

absolute temperature (in these experiments, 310 K), m the number of growth units

represented by v, and RS the relative supersaturation.

Crystal growth. COM seeds were

produced using the dimethyl oxalate method [10]. First, a 2.5mM calcium

chloride solution was prepared, and the pH adjusted to 4.7 with dilute ammonium

hydroxide. Calcium chloride solution (150 mL) was added to 100 mL of ammonium

acetate— acetic acid buffer (2.5 M with respect to each) into a 500 mL

polymethylpentene plastic flask; then dimethyl oxalate (10 g) was added. The

flask was tightly closed and heated in an oven at 900C for 2.5 h,

followed by rapid cooling to room temperature. Crystals were collected by

centrifugation, washed with a RS 1 solution in NaCl— HEPES buffer, and diluted

to 0.311 mg mL-1. Crystals produced were monoclinic, with an average

length of 3.5 mm (fig. 4c).

The advantage of this method is that a substantial quantity of large

morphologicaily well described crystals were produced by slowly generating

oxalate in situ under zero-order kinetic conditions. Surface area of 1700 cm2

g-1 was determined using the BET surface area analysis (Porous

Materials, Inc.).

Equal volumes of calcium and oxalate reactant solutions were added to a

50 mL polymethylpentene flask maintained at 370C in a water bath (14C-oxalate

was added as tracer to oxalate solutions). COM seed slurry (0.062 mg mLt final

concentration) was added to initiate crystallization. At 5 mm intervals,

aliquots were removed and filtered through a 0.22 ~.tm Nucleopore filter (25

mm). The filtrate was dispensed into a scintillation vial with 100 ~.tL normal

HCI and scintillation cocktail (Scintiverse II). Samples were counted using a

Beckman LS 3801 liquid scintillation counter. The crystal-laden filters were

also counted after rinses with 3 mL of RS 1 solution. Oxalate concentrations

were determined, and RS values were calculated assuming a 1 : 1 calcium oxalate

precipitate. We should note that under these conditions [‘4C]

oxalate exchange with seeds should be negligible. To estimate the influence of

citrate on the crystal growth rate of calcium oxalate monohydrate, we used the

parabolic growth rate law: (-d RS/dt = kst[RSi - RS¥2). Integrating

this equation gives

kstt = (RSt - RS¥)-1

- (RSt - RS¥)-1,

where

t is the time interval from the beginning of crystallization (in

seconds), RS~ the relative supersaturation at time t, RSi the

initial relative supersaturation, RS¥. the relative

supersaturation at equilibrium (defined as 1), K the crystal growth rate

constant (s-1), and st the total crystal surface

area at time t. We calculated st

by matching fractional changes in total seed mass as determined from the

growth experiments to fractional changes in volume and correlated these to fractional

changes in surface area using the surface area of the seeds (1700 cm2 g1)

as s0. Volume and surface were related to each other based on the

geometry of hexagonal prisms closely similar in morphology and dimension to the

actual seeds as observed by SEM.

Morphology.

Samples for microscopic analysis were taken at specified intervals

after beginning

the

experiment; typically, a 0.5 mL aliquot was removed and filtered through a 0.22

mm Nucleopore

filter (13 mm). In the nucleation experiments, crystals were fixed after five

and ten mm for each of the twelve solutions. For the crystal growth

experiments, crystals were filtered after 0, 3, and 24 h for RS 20 solutions

with and without citrate. Crystals were then gold-coated and examined by

scanning electron microscopy. Surface analysis was performed using a KEVEX

X-ray spectrometer; no surface contaminants were found.

Particle

characterization. Experimental systems the same as those used for

lag-phase measurements were employed for purposes of particle

characterization. Aliquots of these solutions were taken 20 mm after mixing

[11]. Total particle number and mode particle diameter (equivalent spherical

diameter) were measured using an Elzone 80 XY (Particle Data, Inc.).

3. Results

To understand the action of

citrate, we first applied a lag-phase kinetic analysis in which the appearance

of crystals was evaluated turbidimetrically using a spectrophotometer at a

non-absorbing wavelength (530 nm). When data collected in these experiments

were analyzed using the Gibbs-Thomson equation as discussed above, plots of

ln(1/r) versus (ln RS)-2 gave slopes of -62.5 + 1.92 for control

and -49.5 + 6.26 for the

experiment with citrate; intercepts were 1.03 + 0.2 and —0.72 ±

0.6 respectively. The slopes were further analyzed by converting them into

values for the apparent interfacial energy for nucleation. This was done by

solving the equation

slope = (—16ps3v2/3k3T3), (2)

taken

from the linearized form of the Gibbs-Thomson equation (cf. eq. (1)). Apparent

interfacial energy for the control was 28.9 erg cm2, and for the

citrate system it was 26.8 erg cm2. These values may be compared

with those derived for systems very similar to our control system. In earlier

work [1], we found a value of 27.3 erg

Fig. 2. Gibbs—Thomson nucleation plot: (●) control slope = -63±6.3,

intercept = 1.0±0.60, r2 = 0.96; (▲) 3.5mM citrate slope = -50± 1.9,

intercept=0.71±0.18, r2 = 0.99.

cm2and Finlayson

[11] gave the value 31.1 erg-2 cm.

As another way of looking at nucleation, we examined particle

production in our nucleating systems. Based on the observations of Finlayson

[11], we expected total particles, N, to be a rather flat and somewhat noisy

function of relative supersaturation in this range of RS. This proved to be

the case, however, we did detect statistically significant differences in N and

in equivalent spherical diameter between the control and citrate systems.

Without citrate, the nucleating systems produced an average of 3.46 (± 1.94) x

iO~ particles per liter, with an average mode diameter of 12.4 + 3.8 ~tm. With

citrate, N

was 7.14 (± 2.78) x i0~ particles per liter, with an average mode

diameter of 8.2 ± 1.3 ~.tm.

Although there was a relatively small but significant difference between the apparent interfacial energies of the control and experimental systems, there was a considerable difference between the lag-times in the two sets of solutions at corresponding relative supersaturations. Table 1 shows that lag-times in citrate systems were invariably longer than the control systems by an average of 75%. We believed that the interfacial energies were an accurate reflection of nucleation in our experiments, and that the discrepancy in lag-times could be explained by growth inhibition due to the presence of citrate.

Crystal growth studies did indeed show a significant difference in

growth rates at a citrate

Table 1

Kinetics of

calcium oxalate monohydrate nucleation in the

absence and

presence of 3.5mM citratea)

Relative Observed lag times (s)

supersaturation Control 3.5mM citrate

20 400±44 560±26

22 250±14 350±80

24 170+66 290±47

28 130±57 170±61

33 70±19 140±33

37 30±12 90±17

a)Note that the

uncomplexed calcium ion concentrations for each pair of control and citrate

samples were the same, based on calculations with EQUIL.

Fig. 3. Determination of crystal growth rates: (e) control, K = 4.7±0.33X iO~ cm2

~ intercept = 0.093+0 052 r2 =

0.98, N=

7; (A) 3.5mM citrate K= 11+0

10x105 cm2 ~, intercept = 0.068±0.018, r2 = 0.96, N= 7.

concentration

of 3.5mM (see fig. 3). Again, we sought to control the solution very closely so

that differences in crystal growth rates could be clearly attributed to

citrate. The surface normalized crystal growth rate in the control was 2.36 (±

0.16) x 106 51 cm2,

whereas for the citrate system it was 0.66 (±0.03) x 106 51 cm2.

The reduced growth rate of COM in the presence of citrate allowed us to explain

the differences in particle counts and sizes we had observed. It was clear that

growth inhibition would cause smaller particles as we had seen with citrate,

but because growth was delayed, the relative supersaturation, and therefore the

nucleation rate, did not fall as quickly, consequently, more particles were produced.

Taken by itself, the doubling of the lag-times with citrate might have been

interpreted as inhibition of nucleation while the doubling of the particle

counts might have been interpreted as promotion of nucleation. By bringing

several techniques to bear on this closely controlled experimental design, a

self-consistent view of the action of citrate emerged which explained these

apparently conflicting results.

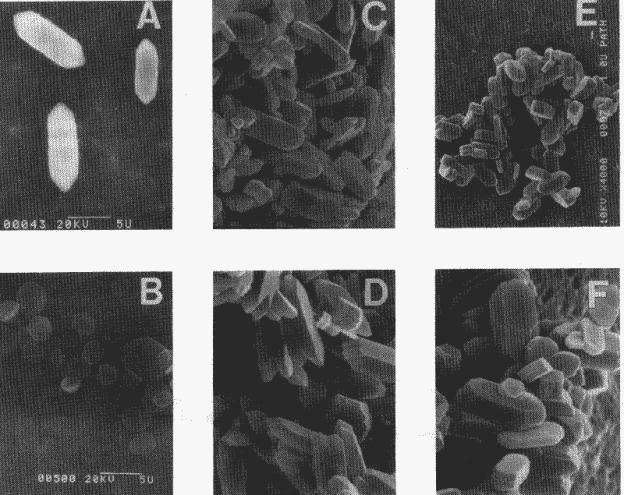

Fig. 4. Photographs

of COM using scanning electron microscopy. Nucleation experiments at 10

mm: (a) RS 20 control; (b) RS 20 with 3.5mM citrate. Crystal growth

experiments: (c) COM seeds at time zero; (d) COM seeds grown for 3 h in RS 20

control solution; (e) COM seeds grown for 3 h in an RS 20 containing 3.5mM

citrate solution (magnification: 4000 x); (f) COM seeds

grown

for 3 h in RS 20 containing 3.5mM citrate solution (magnification: 7800 x).

As

in our previous report on nucleation, we attempted to model these results with

our crystallization simulation program, PSD [1,12]. These efforts are still in

the preliminary stages, but early results are encouraging because the

simulations do reflect the general trends of the experiments.

The effect of citrate was seen in a striking way in electron

micrographs of crystals from the nucleating systems. Fig. 4a shows crystals of

COM nucleated in the control system. These crystals had a characteristic

morphology for COM; they were twinned (as in fig. 4c) and had a prominent

elongated hexagonal face. In the presence of citrate, however, the crystals

were broader and flatter with an aspect similar to regular hexagons (fig. 4b).

Seed crystals used in seeded growth experiments (fig. 4c) were not altered much

in shape by either control systems (fig. 4d) or systems containing citrate

(figs. 4e and 4f).

4. Discussion

In evaluating the inhibitory

action of citrate, we found that compensation for the complexation of cations

made a very considerable difference in the observed nucleation and growth rate

behavior. To achieve equal uncomplexed calcium ion concentrations in the

absence and presence of citrate, the total calcium concentration had to be

raised significantly. In the control samples, uncomplexed calcium ion

corresponded to about 85% of the total calcium ion concentration, whereas it

was only 25% of total calcium in the presence of citrate. Failure to account

for the importance of complexation would have resulted

Fig. 5. Computer simulation of COM crystal growth. (a) Morphology

of control crystal as predicted by maturing each crystal face. Initial

“nucleus” has an identical morphology. (b) Morphology of crystal computer grown

in a 3.5mM citrate solution by restricting growth on (010) face. See fig. 4b.

in

misleading inferences about apparent differences in the kinetics of nucleation

and crystal growth. By using EQUIL, however, we could correct for these

chelation effects by citrate, and our data show that the presence of calcium

citrate complex and citrate ions resulted in about a 70% decrease in crystal

growth rate. This observation indicates that uncomplexed citrate and/or

calcium citrate must reduce the efficiency of adding calcium ion, oxalate ion,

on calcium oxalate complex to crystal growth sites.

From our kinetic and morphological studies of calcium oxalate

monohydrate crystals, we now propose that citrate adsorbs preferentially to one

crystal face, thereby altering the morphology of the crystals during the

further accretion of calcium oxalate into the crystal. As shown in fig. 5, we

could start with a common initial crystal morphology and allow crystals to

“grow” using a computer program that represented changes in crystal mass as a

change in total volume of the geometrically defined crystal. Without any change

in apparent rates of addition to the various crystal faces, morphology was

maintained; however, by restricting growth on the (010) face, increased

addition to the other faces resulted in hexagonal plates shown in this figure.

Using the X-ray crystallographic data of Deganello and Piro [13] we developed

a specific proposal regarding this binding behavior. Of the three major planes

defining the calcium oxalate monohydrate crystal (i.e., the (010), (101), and

the (001) planes), only the first

two

have oxalate groups parallel to the face, and citrate would most probably

replace oxalate ion by binding on the (101) face.

In any case, the morphological changes due to the adsorption of citrate may be

significant in urolithiasis, because crystal—cell interactions and crystal

aggregation processes are both likely to be influenced by changes in crystal

morphology. For example, Wiessner et al. [14] reported that COM crystals

exhibit a much higher capacity to cause red blood cell membranolysis than do

dihydrate crystals. Likewise, the adhesion of COM crystals to papillary cells

are likely to be affected by the contour and nature of the various faces of

calcium oxalate crystals. Crystal aggregation may also depend upon morphology,

and the hexagonal plates formed in the presence of citrate may aggregate more

readily. All of these considerations have led us to initiate a longer term

study using stereo-chemical considerations as the basis for molecular

recognition at crystal interfaces [15]. Such efforts have already provided many

valuable inferences regarding changes in crystal morphology arising from

face-specific interactions of crystals and growth inhibitors [16,17]. While

clearly beyond the scope of our present work on citrate, we are attracted by

the potential of the molecular recognition approach which may reveal how

low-molecular-weight inhibitors such as citrate and pyrophosphate, as well as

macromolecules (e.g., nephrocalcin and Tamm—Horsfall proteins) affect crystal

growth processes.

Finally, although nucleation and growth processes in the case of

calcium oxalate monohydrate appear to overlap during the initial lag-phase of

precipitation, our earlier studies [1] as well as those of Söhnel and Mullin

[18] indicate that such lag-phase kinetics can be treated phenomenologically

in terms of the Gibbs—Thomson formulation. Nevertheless, as we probe further

into the details of the early steps in COM crystallization using the tools of

molecular recognition theory to establish a structural perspective, we

recognize that more advanced theoretical treatments of precipitation could be

helpful. Such models might, for example, allow for the deconvolution of the

overlapping time domains of nucleation and growth steps.

References

[1] C.M. Brown, D.K. Ackermann,

D.L. Punch and B. Finlayson, J. Crystal Growth 108 (1991) 445.

[2] I. Greenwald, J. Biol.

Chem. 124 (1938) 437.

[3] B. Kissen and MO. Locks,

Soc. Expt. Biol. Med. Proc. 46 (1941) 216.

[4] IS. Light and H.H. Zinsser,

Arch. Biochem. Biophys. 92 (1961) 487.

[5] H. Sidhu, R. Gupta, S. Thind

and R. Nath, Urol. Res. 14 (1986) 299.

[6] P. Werness, C. Brown, L.

Smith and B. Finlayson, J. Urol. 134 (1985) 1242.

[7] P. Curreri, G.Y. Onoda and

B. Finlayson, J. Colloid Interface Sci. 69 (1978) 170.

[8] J.H. Adair, Coagulation of

Calcium Oxalate Monohydrate Suspensions, PhD Dissertation, University of

Florida, Gainesville, FL (1981).

[9] AG. Walton, The Formation

and Properties of Precipitates (Kreiger, Huntington, NY, 1979) pp. 3—7.

[10] L. Gordon, M.L. Salutsky

and H.H. Willard, Precipita

tion from Homogeneous Solution (Wiley, New York, 1959) pp. 57—58.

[11] B. Fiolayson, Kidney

Intern. 13 (1978) 344.

[12] B. Finlayson, Comment on

the round table discussion on theoretical models related to urolithiasis, in:

Urolithiasis and Related Clinical Research, Eds. P.O. Schwille, L.H. Smith,

W.G. Robertson and W. Vahlensieck (Plenum, New York, 1985) pp. 923—933.

[13] S. Deganello and O.E.

Piro, Neues Jahrb. Mineral. Monatsh. H 2 (1981) 81.

[14] J.H. Wiessner, G.S.

Mandel and N.S. Mandel, J. Urol. 135 (1986) 835.

[15] I. Weissbuch, L. Addadi,

M. Lahav and L. Leiserowitz, Science 253 (1991) 637.

[16] J.D. Foot and E.A:

Colbourn, J. Mol. Graphics 6 (1988) 93.

[17] I. Weissbuch, L. Addadi,

L. Leiserowitz and M. Lahav, J. Am. Chem. Soc. 110 (1988) 561.

[18] 0. Sdhnel and J. Mullin, J. Colloid Interface Sci. 123 (1988) 43.